Predictive Analytics for Industrial Maintenance

Predictive analytics is transforming industrial maintenance by moving beyond reactive repairs to proactive interventions. This advanced approach leverages data from machinery and operational systems to forecast potential equipment failures, enabling maintenance teams to schedule interventions precisely when needed. By anticipating issues before they arise, industries can significantly reduce unexpected downtime, optimize resource allocation, and enhance overall operational efficiency across various sectors. This strategic shift is crucial for businesses aiming to maintain competitive edge and foster resilience in their production and supply chain processes.

Understanding Predictive Analytics in Industrial Settings

Predictive analytics in an industrial context involves using data, statistical algorithms, and machine learning techniques to identify the likelihood of future outcomes based on historical data. For industrial maintenance, this means collecting vast amounts of data from sensors embedded in machinery, production lines, and other critical assets. This data, which can include vibration patterns, temperature fluctuations, pressure readings, and operational hours, is then processed and analyzed to detect anomalies or patterns indicative of impending equipment failure. This innovative application of technology allows for a shift from time-based or reactive maintenance to a condition-based approach, significantly improving asset reliability and operational stability for a wide range of industrial applications.

Benefits for Manufacturing and Production Efficiency

The integration of predictive analytics offers substantial benefits for manufacturing and production efficiency. By accurately forecasting when a piece of machinery is likely to fail, organizations can schedule maintenance during planned downtime, avoiding costly interruptions to production schedules. This proactive strategy not only extends the lifespan of valuable assets but also optimizes overall equipment effectiveness (OEE). Reduced unplanned downtime means higher throughput, more consistent product quality, and better utilization of production capacity. The digitalization of maintenance operations through analytics provides manufacturers with actionable insights, enabling them to make data-driven decisions that enhance their entire operational framework.

Impact on Supply Chain and Logistics Management

The reliability of industrial machinery has a direct and profound impact on supply chain and logistics management. Unexpected equipment breakdowns can cause delays in production, leading to missed deadlines, increased inventory holding costs, and disruptions throughout the entire supply chain. Predictive analytics mitigates these risks by ensuring that production assets operate reliably. This stability allows for more accurate production planning and better coordination with logistics operations, ensuring that goods are produced and shipped on schedule. For global enterprises, maintaining operational continuity across various facilities is paramount, and predictive maintenance plays a key role in achieving this, supporting a more resilient and efficient global supply chain.

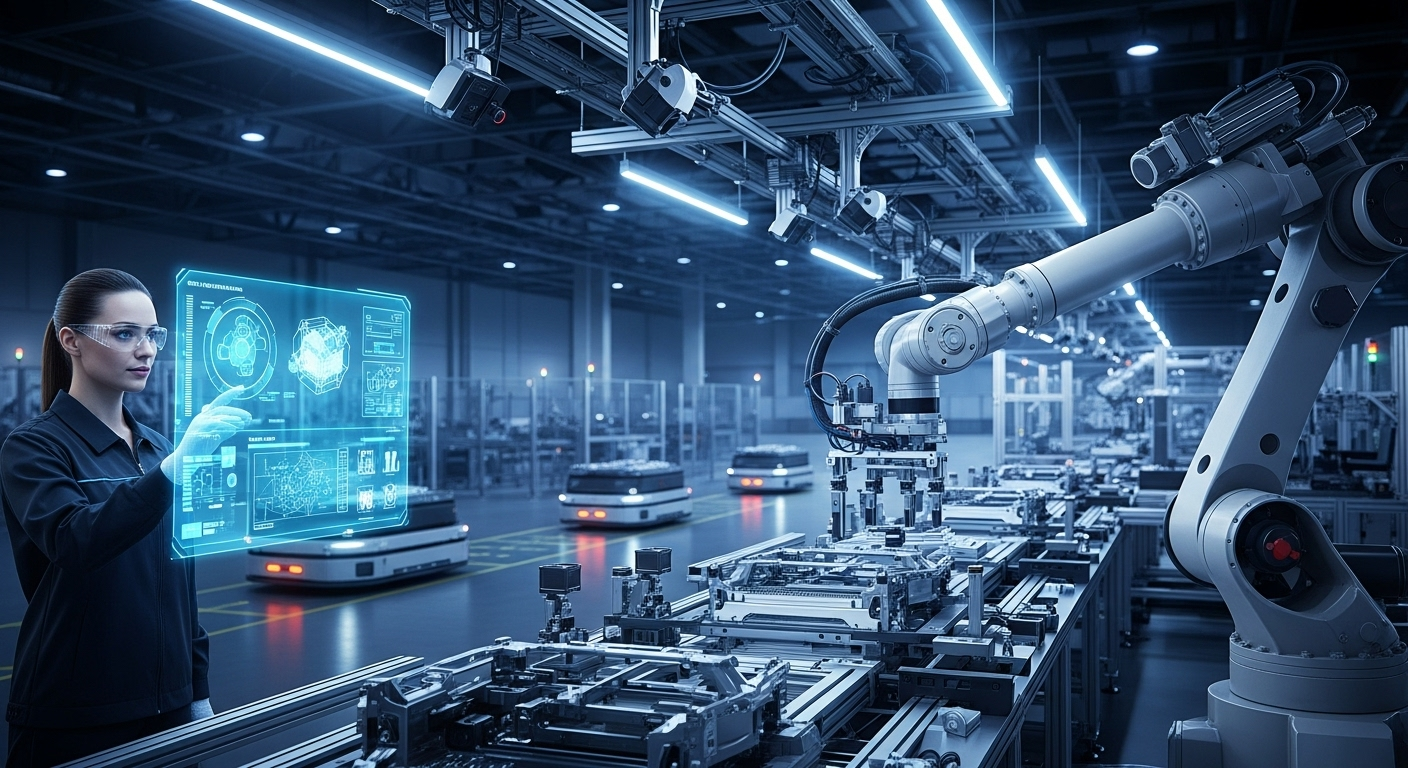

Integrating Automation and Robotics for Enhanced Maintenance

Predictive analytics is increasingly intertwined with automation and robotics to create highly efficient maintenance systems. Once analytics identifies a potential issue, automated systems or robotic tools can be deployed to perform inspections, diagnostics, or even minor repairs without direct human intervention. This integration enhances safety, especially in hazardous environments, and allows for faster response times. The workforce, in turn, can shift their focus from routine, manual tasks to more complex problem-solving, system oversight, and strategic planning. This evolution in technology not only boosts efficiency but also elevates the skill sets required, fostering a more advanced and adaptable industrial workforce.

Ensuring Data Security in Industrial Analytics

As industrial operations become more digitalized and reliant on data-driven insights, ensuring robust cybersecurity measures is critical. The vast amounts of operational data collected for predictive analytics, including sensitive performance metrics and proprietary process information, must be protected from unauthorized access, cyber threats, and data breaches. Implementing strong encryption, access controls, and continuous monitoring protocols is essential to safeguard these valuable data streams. A secure analytics infrastructure is foundational to maintaining trust in the data and the integrity of the predictive models, preventing potential disruptions to production and protecting intellectual property across the enterprise.

Sustainability and Future Trends in Industrial Analytics

Predictive analytics also plays a significant role in promoting sustainability within industrial operations. By optimizing maintenance schedules and extending the life of machinery, it reduces the need for premature replacements and minimizes waste generated from broken parts. Optimized equipment performance also leads to more efficient energy consumption, contributing to a smaller carbon footprint. Looking ahead, innovation in industrial analytics continues to advance with the integration of artificial intelligence and edge computing, allowing for even faster, more precise predictions. The trend towards greater digitalization and interconnectedness will further enhance the capabilities of predictive analytics, making industrial processes more efficient, sustainable, and resilient in the long term.

Predictive analytics is fundamentally reshaping industrial maintenance practices. By leveraging data and advanced algorithms, industries can achieve unprecedented levels of operational efficiency, asset reliability, and cost savings. This proactive approach not only minimizes disruptions but also supports strategic planning across manufacturing, supply chain, and logistics. As technology continues to evolve, the integration of automation, robotics, and robust cybersecurity will further solidify predictive analytics as an indispensable tool for modern industrial enterprises, driving both efficiency and sustainability into the future.